Description

FA Series — Carbon Steel Flash Arrestors

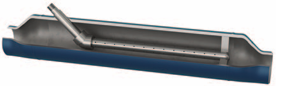

The FA Series Flash Arrestors are carbon steel devices installed in condensate return systems where high-pressure condensate is introduced into low-pressure return piping. Their internal sparge pipe design reduces the effects of water hammer by diffusing incoming condensate and controlling flash steam formation. These units are built for rugged industrial service and are suitable for Schedule 80 shell construction with standard or optional high-pressure inlet piping.

Water Hammer Reduction

The FA Series is specifically designed to minimize shock and vibration caused by flash steam in condensate return lines. By evenly distributing condensate through an internal sparger, the flash arrestor absorbs energy and prevents sudden pressure surges that can damage piping and equipment.

Material Specification

- Body: Carbon Steel

Technical Specification

- Inlet / Outlet Sizes: 1 1/2", 2", 2 1/2", 3", 4"

- Outlet Connection: Butt Weld (Standard)

- Inlet Connection: NPT or Butt Weld (Optional)

- Shell Construction: Schedule 80

- Maximum Operating Pressure: Up to 300 PSIG

Operating Principles

High-pressure condensate enters the FA Series flash arrestor through the inlet connection and is dispersed through an internal sparge pipe. This controlled distribution allows flash steam to form gradually rather than violently, reducing turbulence and eliminating water hammer. The conditioned condensate and flash steam then exit smoothly into the return line.

FA Series Models

| Model Code | Shell Diameter | HP Inlet Size | Connection Type | Weight (lbs) |

|---|---|---|---|---|

| FA-16-BW-20-14-N-SS | 4" | 1" | Butt Weld | 55 |

| FA-17-BW-20-14-N-SS | 4" | 1" | Butt Weld | 55 |

| FA-18-BW-20-14-N-SS | 4" | 1" | Butt Weld | 55 |

| FA-19-BW-22-14-N-SS | 6" | 1" | Butt Weld | 90 |

| FA-20-BW-22-14-N-SS | 6" | 1" | Butt Weld | 95 |

| FA-22-BW-23-14-N-SS | 8" | 1" | Butt Weld | 170 |

Applications

- Condensate return systems

- High-pressure to low-pressure condensate discharge

- Steam systems prone to water hammer

- Boiler and plant condensate headers

- Industrial steam and thermal systems

Notes

Standard design uses Schedule 80 shell construction. Optional configurations include NPT inlet connections and higher-pressure inlet piping. Stainless steel internal components are available upon request. Consult factory for application sizing and special configurations.