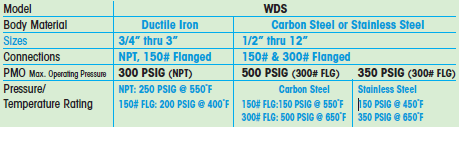

Description

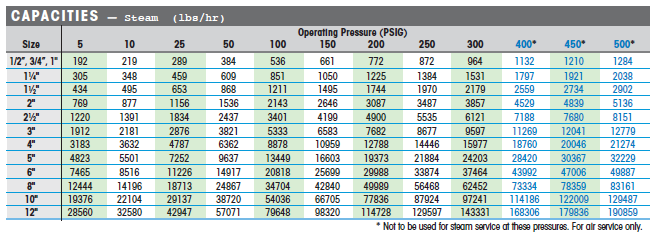

The WDS Series Separators are used for the removal of entrained liquid or solids from steam or air. Effective in applications where the system has an entrained liquid flow rate of up to 40% by weight of the unit’s flow capacity.

Products listed with a 0$ price will be priced after a call to the factory has been made.

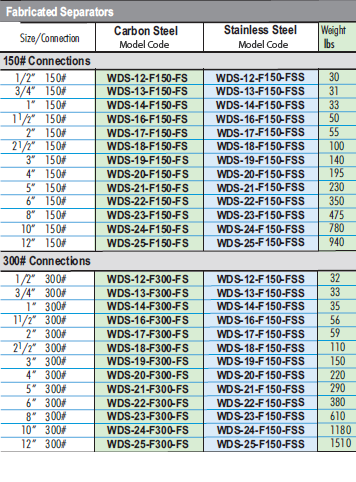

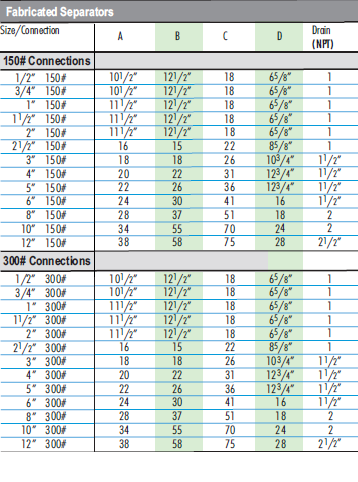

Available in Cast Iron or in Fabricated Steel

Features

- Removes 99% of all particles > 10 microns in size

- Minimum pressure drop

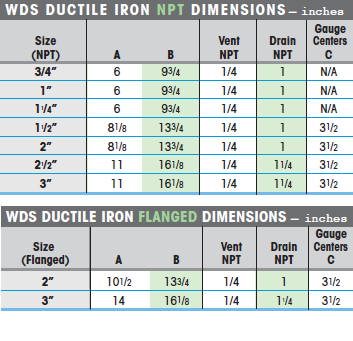

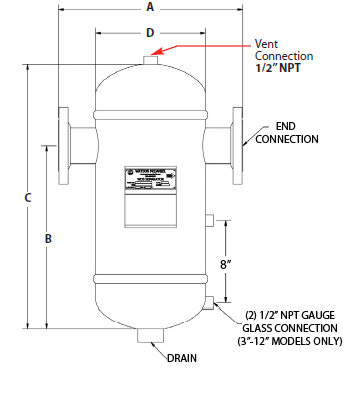

- Standard gauge ports on 1-1/2” to 3” cast units

- Standard gauge ports on 3”–12” fabricated units

- ASME Code constructed

How It Works

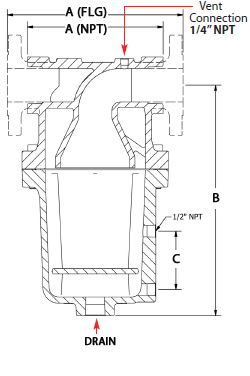

Wet steam enters the inlet of the separator where it is deflected in a centrifugal downward motion. The entrained moisture is separated out by reduction in velocity. Separated liquid then falls below the cyclone drip plate where it cannot be re-entrained. Dry steam or air then flows upward and exits through the outlet of the separator.

Installation and Maintenance

The WDS Air/Steam Moisture Separator must be installed in a horizontal run of pipe. Exercise standard piping and structural practices when installing this unit. Proper drainage of the separator utilizing a float & thermostatic steam trap or liquid

NOTE: We will contact you during order fulfilment to discuss shipping and handling costs for products weighing more than 150 pounds. These costs will be billed separately.